RageWire® Automation Guarding Solutions

Robotic Automation Guarding Evolved

Discover the future of robotic guarding with RageWire® Automation Guarding Solutions. Our innovative and cost-effective solution revolutionizes machine safety while conforming to ANSI/RIA standards. Designed with efficiency and simplicity in mind, RageWire® offers a frameless guarding system comprising just five components. Experience advanced protection for your robotic applications while ensuring a streamlined and productive workspace.

RageWire® Automation Guarding system Features

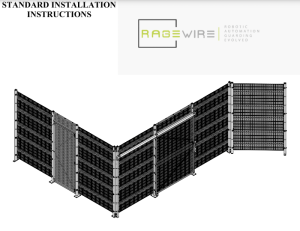

RageWire® keeps it simple with the entire product line consisting of one standard wire mesh panel (5′ wide), universal posts (6′, 7′, 8′ tall), one bracket, two door options, and electric interlock integration. For a comprehensive understanding of the various product components and options across our entire range, be sure to visit the Product Components & Options page.

Post

Pivot posts allow for easy management of corners with 160° of rotation.

Panel

V-bend in mesh adds structural integrity and allows for wire management.

Bracket

Carriage bolt attaches bracket to post and machine screw secures mesh to bracket.

Door

Easy-install swing and slide doors come standard; BeastWire™ doors are available for specialized applications.

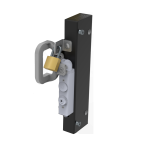

Lock

Standard doors come with pull handle and padlock hasp; Fortress Interlocks (shown) available for added security.

Finish

The standard finish, featuring yellow posts and black panels, serves as a clear visual safety cue.

RageWire® Automation Guarding system Benefits

We understand the importance of purchasing a protective guarding cage for your valuable robotic investment. With RageWire® Automation Guarding Solutions, our aim is to simplify this process by providing an approach that is seamless and cost-effective. With our innovations, all you need to do is plant a post and hang a panel, making the automation guarding fencing installation process intuitive and hassle-free.

Rest assured, our RageWire® automation guarding solutions are designed to meet ANSI/RIA standards, giving you peace of mind and ensuring the utmost safety for your robotics.

01.

Strength and Rigidity

V-bend mesh panel design adds strength and rigidity to the system, along with a built-in, recessed cable management cavity

02.

Easy Field Modifications

Unframed automation guarding panels allow for easy field modifications

03.

Quick Panel Lift-Out System

Saddle pocket brackets provide a quick panel lift-out system for machine access and fast panel reengagement

04.

Easy Corner Management

The unique pivot post design allows for easy management of corners with 160° of rotation

05.

Conforms to Industry Standards

1.25” x 4” wire mesh opening conforms to RIA/ANSI Standards allows for a 17.5” distance to hazard

06.

No Disengage Upon Impact

All hardware comes secured to the bracket and will not disengage upon impact

07.

4″ Sweep Space

4″ sweep space for easy cleaning access

08.

Fortress Interlocks

Swing and slide doors incorporate with Fortress interlocks for a secure system

09.

Universal Post Design

A universal post design allows for easy mounting of photo eyes and light curtains

Ragewire® automation guarding system Resources & Downloads

RageWire® automation guarding Videos

RageWire® wire mesh automation Guarding Applications

Ragewire® machine guarding Case Studies

Unlock the potential of RageWire® Automation Guarding panels with our collection of impactful case studies, showcasing real-world applications and the proven effectiveness of our innovative solutions.

Overcoming Safety Challenges: How Modular Machine Guarding Improved a Beverage Manufacturer’s Operations

The Challenge A global beverage company needed to ensure the safety of their workers across a variety of unique production lines without interrupting their operations.

RageWire® wire mesh automation Guarding Blogs & Case Studies

Learn all about RageWire® Automation Guarding! Our blogs keep you up-to-date on industry trends and best practices to optimize your manufacturing environment. Plus, see RageWire® in action with real-world case studies showcasing its effectiveness.

Overcoming Safety Challenges: How Modular Machine Guarding Improved a Beverage Manufacturer’s Operations

The Challenge A global beverage company needed to ensure the safety of their workers across a variety of unique production lines without interrupting their operations.

Understanding the Importance of the “Distance to Hazard” in the Safeguarding Industry

Machine guarding is necessary for any business that utilizes machinery with moving parts, such as manufacturing facilities, industrial plants, warehouses, construction sites, and any other

The Importance of Machine Guarding: Protect Your Business From Workplace Injuries

SpaceGuard Products knows the importance of machine guarding to businesses large and small. In this blog, we will explore the importance of machine guarding and

RageWire® wire mesh automation Guarding Blogs

Explore our informative and insightful blogs, dedicated to showcasing the latest trends, best practices, and industry insights related to RageWire® Automation Guarding, empowering you with valuable knowledge for a safer and more efficient manufacturing environment.

Understanding the Importance of the “Distance to Hazard” in the Safeguarding Industry

Machine guarding is necessary for any business that utilizes machinery with moving parts, such as manufacturing facilities, industrial plants, warehouses, construction sites, and any other

The Importance of Machine Guarding: Protect Your Business From Workplace Injuries

SpaceGuard Products knows the importance of machine guarding to businesses large and small. In this blog, we will explore the importance of machine guarding and